woolen fabric made from twisted yarn, late 13c., from Worstead (Old English Wurðestede), town in Norfolk where the cloth originally was made.

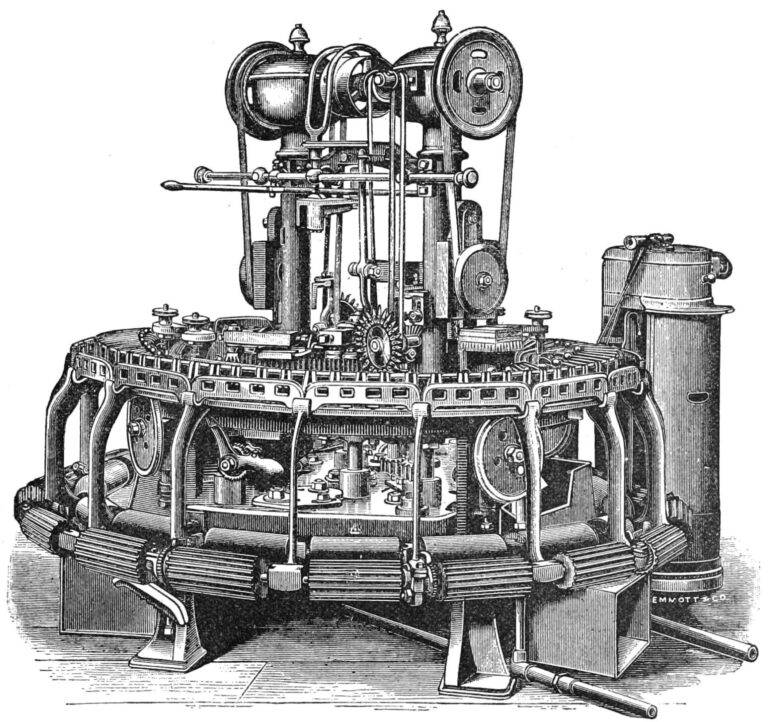

Both worsted and woollen spun wool find applications in knitted fabrics. Worsted wool fabric, prized for its quality, is predominantly employed in the creation of tailored garments such as suits. In tropical-weight worsteds, tightly spun, straightened wool combined with a looser weave allows for excellent airflow through the fabric. Additionally, worsted wool is used in the production of carpets, clothing, hosiery, gloves, and baize.

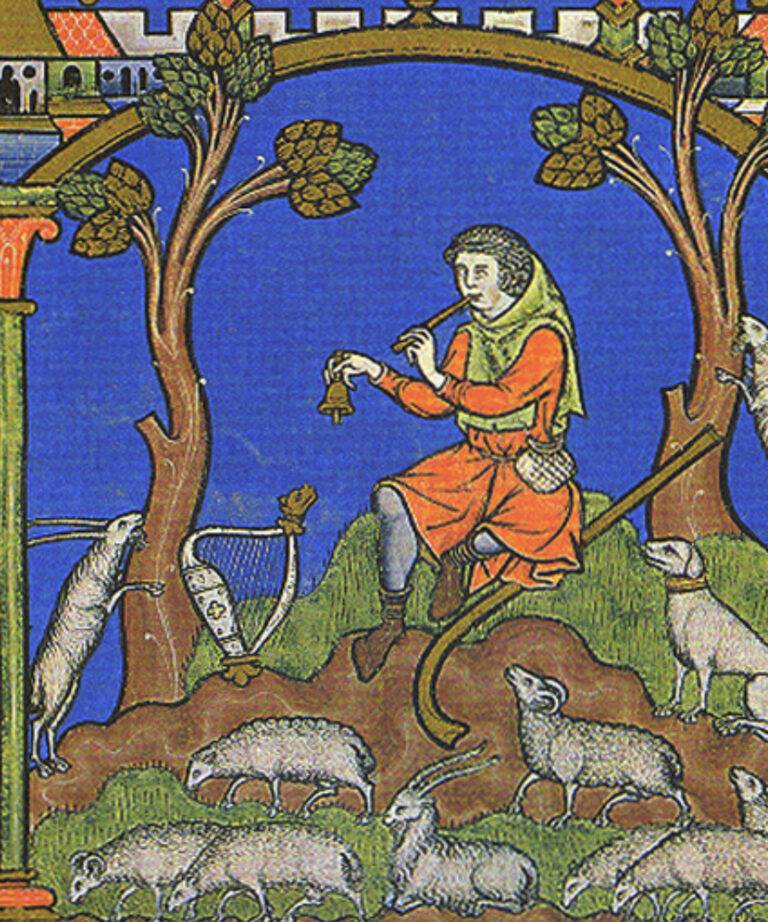

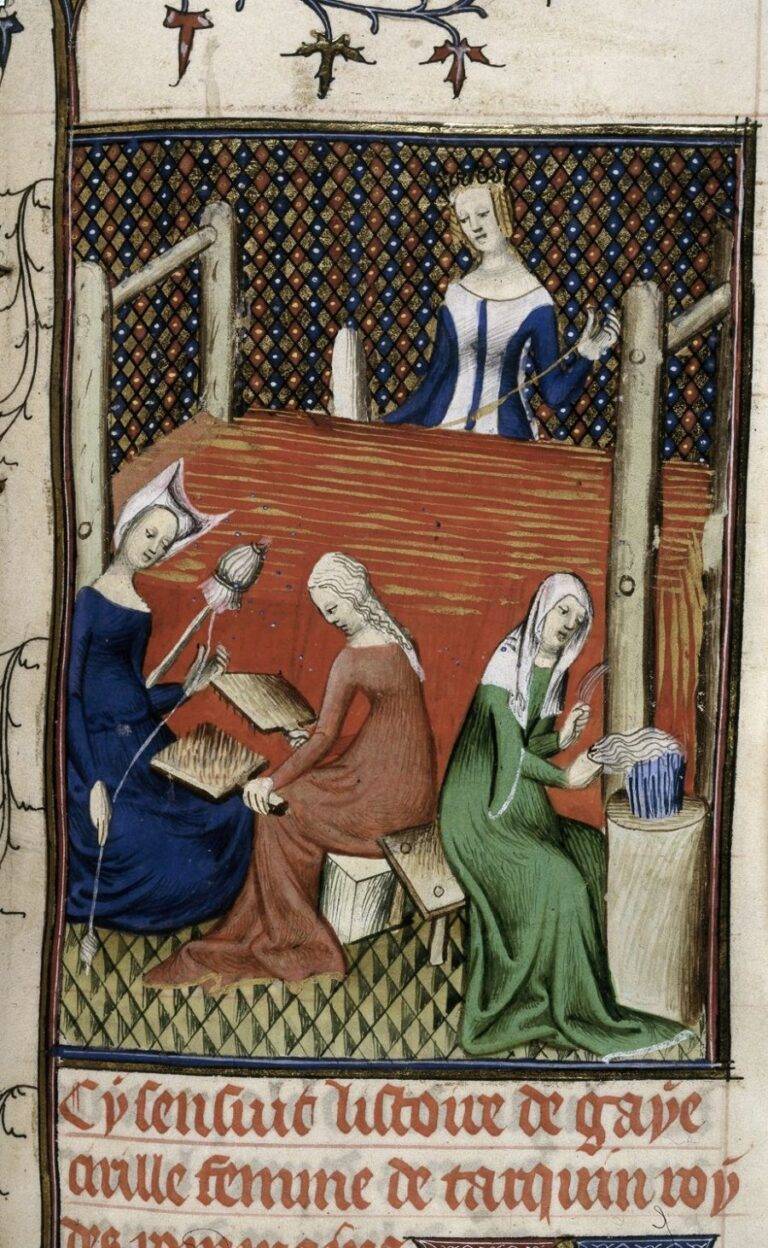

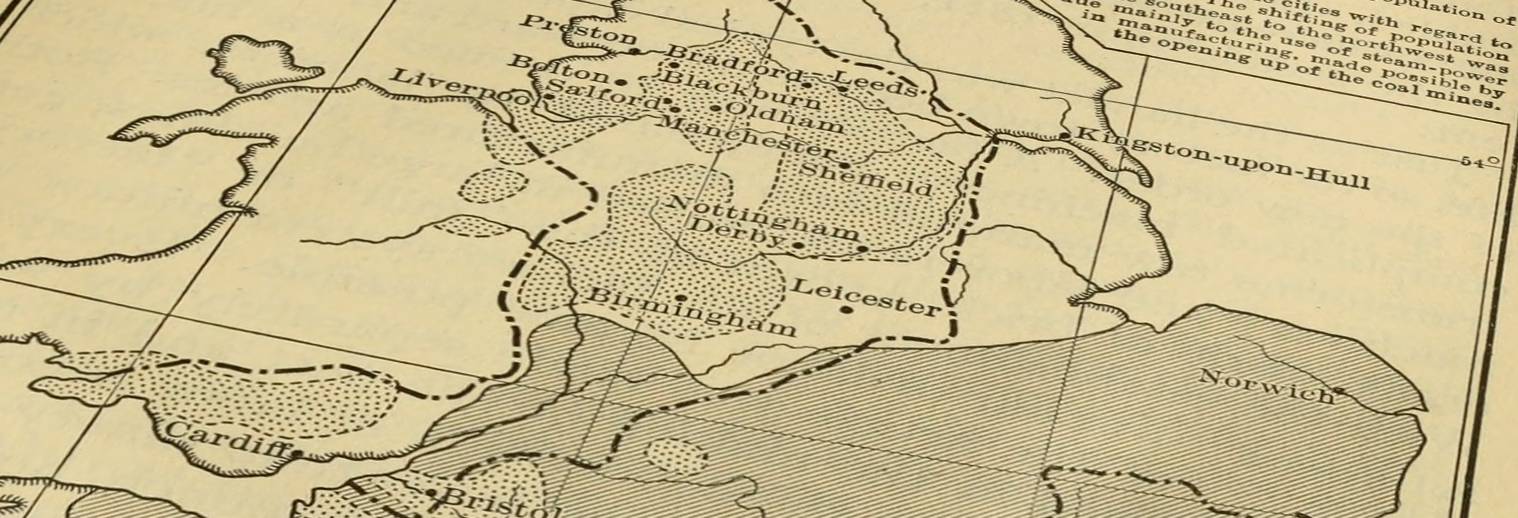

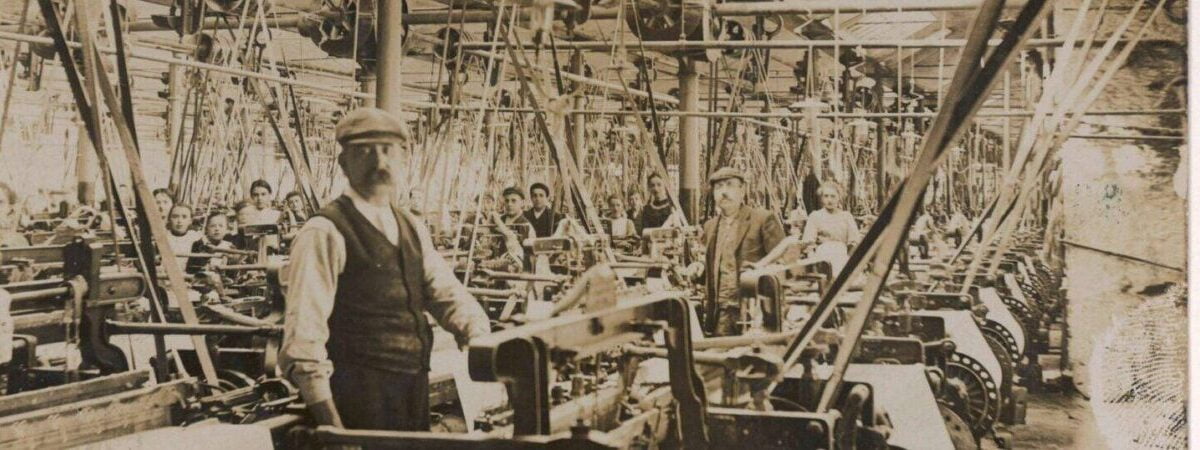

Worsted is a high-quality type of wool yarn, a category of yarn weight, and the fabric crafted from this specific yarn. Its name originates from Worstead, a village nestled in the English county of Norfolk. During the 12th century, this village, along with North Walsham and Aylsham, burgeoned into a thriving hub for yarn and cloth production. This transformation was driven by the changing agricultural landscape, as pasture enclosure and soil enrichment made the East Anglian region unsuitable for traditional sheep breeds. Concurrently, weavers from the County of Flanders migrated to Norfolk.”Worsted” yarns and fabrics are distinct from woollens, despite both being derived from sheep’s wool. Worsted is renowned for its superior strength, fineness, smoothness, and durability compared to its woollen counterpart.Worsted yarn was traditionally spun from the long-staple wool of pasture-raised sheep breeds like Teeswaters, Old Leicester Longwool, and Romney Marsh. Instead of carding, this wool was subjected to a meticulous process that included washing, gilling, combing (using heated long-toothed metal combs), oiling, and finally spinning. When woven into fabric, worsteds underwent scouring but not fulling.

Both worsted and woollen spun wool find applications in knitted fabrics. Worsted wool fabric, prized for its quality, is predominantly employed in the creation of tailored garments such as suits. In tropical-weight worsteds, tightly spun, straightened wool combined with a looser weave allows for excellent airflow through the fabric. Additionally, worsted wool is used in the production of carpets, clothing, hosiery, gloves, and baize.

Worsted fabric, historically referred to as “stuff,” boasts a lightweight composition and a coarse texture. The typical weave employed is twill or plain. Notably, twill fabrics like whipcord, gabardine, and serge are often crafted from worsted yarn. When wool is used in worsted fabric, it possesses a natural resilience, swiftly returning to its original shape. However, non-glossy worsted fabrics may develop a shine over time or with repeated abrasion.

Both worsted and woollen spun wool find applications in knitted fabrics. Worsted wool fabric, prized for its quality, is predominantly employed in the creation of tailored garments such as suits. In tropical-weight worsteds, tightly spun, straightened wool combined with a looser weave allows for excellent airflow through the fabric. Additionally, worsted wool is used in the production of carpets, clothing, hosiery, gloves, and baize.

Worsted and woollens, both derived from wool, follow distinct manufacturing processes, yielding markedly different textiles. In worsteds, which undergo more extensive spinning stages, the natural crimp of wool fibers is eliminated during yarn production, while woolens retain this crimp. Woollens are crafted from short-staple yarns, whereas worsted fabrics necessitate longer staple lengths. When woven, the yarns in worsted cloth align parallel to each other, resulting in a smoother surface. In contrast, woollen materials are characterized by their softness, bulkiness, and fuzzy textures.Various terms are employed to describe the softness of textile materials, with “handle” being the wool trade term. Fabrics with a good handle are soft to the touch, whereas those with a poor handle exhibit a harsher feel.

Both worsted and woollen spun wool find applications in knitted fabrics. Worsted wool fabric, prized for its quality, is predominantly employed in the creation of tailored garments such as suits. In tropical-weight worsteds, tightly spun, straightened wool combined with a looser weave allows for excellent airflow through the fabric. Additionally, worsted wool is used in the production of carpets, clothing, hosiery, gloves, and baize.

ウーステッド(梳毛)は、高品質のウールの紡績糸を指します。紡績糸の重量の分類、そしてこの特定の紡績糸から作られた生地です。その名前は、イングランドのノーフォーク州に位置する村、ウーステッドに由来しています。12世紀、この村はノースウォルシャムとアイルシャムとともに、紡績糸と布の製造の盛んな中心地に成長しました。しかし農業地帯の変化によって紡績の技術は推進されます。牧草地の囲い込みと土壌の豊富化により、イーストアングリア地方は伝統的な羊の品種に適さなくなったためです。(※筆者注) その後16世紀後半の宗教改革と経済的な理由によりフランドル伯国の織工がノーフォークに移住しました。フランドル地方の織工は撚糸の技術に優れておりよりこの地方の糸や生地は更に洗練されていくことになります。「ウーステッド」の糸と生地はどちらも羊毛から作られているにもかかわらず、ウーレン(紡毛)とは異なります。ウーステッド(梳毛)は、ウーレン(紡毛)に比べて優れた強度、細さ、滑らかさ、耐久性で知られています。

ウーステッドヤーン(梳毛紡績糸)は伝統的に、テーズウォーター、オールドレスターロングウール、ロムニーマーシュなどの牧草地で育った羊の長繊維ウールから紡がれていました。カードではなくこのウールは、洗浄、ギリング、コーミング(加熱された長い歯の金属のくしを使用)、オイル、そして最後に紡績という入念な工程にかけられていました。生地に織り込む場合、ウーステッドは精練は行われましたが、フルーキング(ウール生地を湿らせて圧力をかけながら熱処理する防縮加工の一種)は行われませんでした。ウーステッドとウーレンの紡績ウールはどちらもニット生地に使用されています。ウーステッドウール生地はその品質が評価されており主にスーツなどの仕立ての服の作成に使用されます。熱帯性梳毛生地ではしっかりと紡いだまっすぐになったウールとより緩い織りによって生地に優れた通気性を提供します。さらに、ウーステッドウールは、カーペット、衣類、靴下、手袋、バイズ(ツイル織りの厚手の布)の製造にも使用されています。