The Lost Pendleton Woolen Mills / Vintage Tags

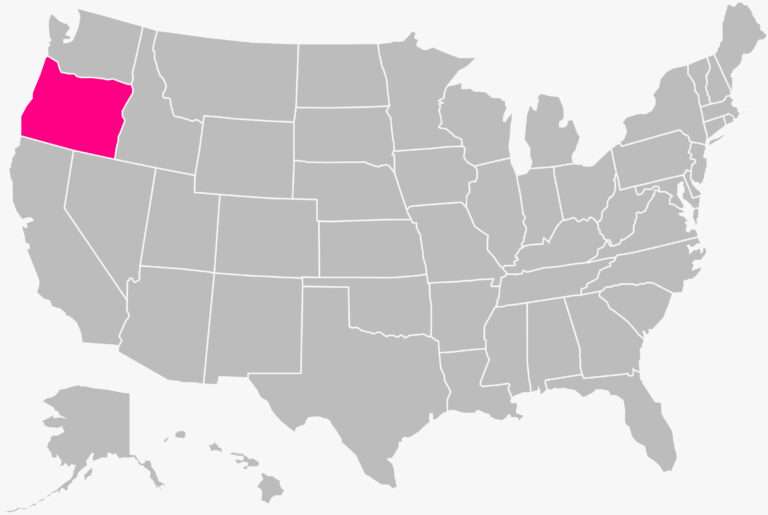

Oregon has been known for its thriving wool industry due to its favorable climate and suitable grazing lands for sheep. The high-quality wool produced in the state has been sought after for various textile applications. It has supported a robust local processing sector, with wool being carefully sorted, cleaned, and processed in facilities within the state, creating employment opportunities and driving economic growth. Additionally, Oregon wool is valued for its versatility and natural properties, making it commonly used in the production of warm and durable clothing items like sweaters, scarves, and socks. Its moisture-wicking ability and insulation properties have made it ideal for outdoor apparel, appealing to both outdoor enthusiasts and fashion-conscious consumers.

The sustainable and eco-friendly nature of wool has also contributed to Oregon’s green initiative, as it is a renewable resource that can be harvested from sheep without causing harm to the animals, and its production process has a relatively low environmental impact compared to synthetic fibers.Furthermore, the wool industry in Oregon has a deep-rooted tradition and heritage, with many ranchers and farmers continuing the practice of raising sheep and producing wool for generations. This adds value to the wool products and attracts consumers looking for authentic and locally-sourced materials.

To ensure the accuracy and current status of this information, it is recommended to consult more recent and up-to-date sources regarding Oregon’s wool industry and its contributions to the textile sector.

また、羊毛は再生可能な資源であり、動物に危害を加えることなく羊から収穫することができ、その生産工程は化学繊維に比べ、環境への影響が比較的少ないです。さらに、オレゴン州の羊毛産業には根強い伝統と遺産があり、多くの牧場主や農家が何世代にもわたって羊の飼育と羊毛の生産を続けている。これはウール製品に付加価値を与え、本物の地元産の素材を求める消費者を惹きつけています。

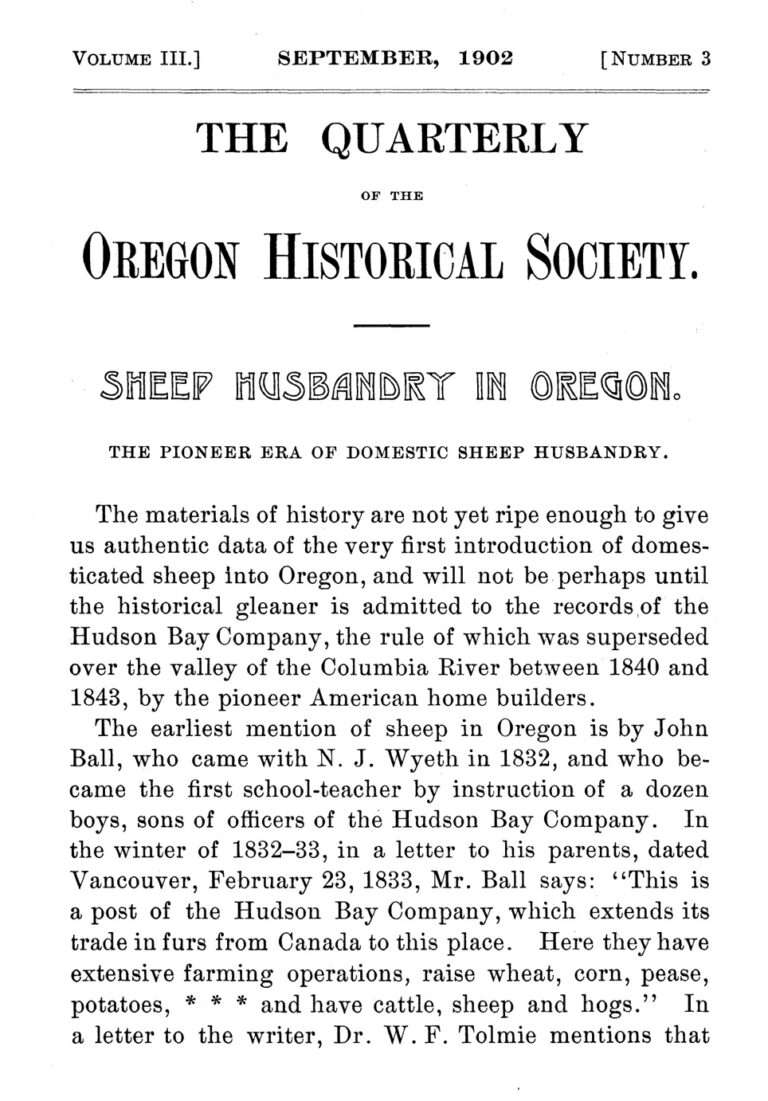

“Oregon Historical Society Quarterly / Sheep farming in Oregon (1902)

The Pioneer Years of Domestic Sheep Rearing.

歴史の資料はまだオレゴンへ最初に家畜化された羊の正確なデータを提供するには十分に熟しておらず、おそらくは歴史的な情報を集める者がハドソン湾会社の記録にアクセスできるようになるまでわからないでしょう。(注釈 HBCはこの頃はビーバーの皮と肉を目的に入植していた) その後この会社は1840年から1843年の間にコロンビア川流域でアメリカのパイオニアたちによって取って代わられます。オレゴンにおける最初の羊の言及は、1832年にN・J・ワイエスと共に来たジョン・ボールによってなされました。彼はハドソン湾会社の幹部の息子たち12人を指導したことで最初の学校教師となりました。1832年から1833年の冬、バンクーバーで書かれた1833年2月23日付の親への手紙の中で、ボール氏は次のように述べています。「ここはハドソン湾会社の拠点であり、カナダからこの地まで毛皮の取引を行っています。ここでは広大な農業が行われ、小麦、とうもろこし、豌豆、じゃがいもなどを栽培し、家畜として牛、羊、豚も飼っています。」 また、執筆者に宛てた手紙で、W・F・トルミー博士が「羊とハンプの利用により、遅くとも1830年代初頭にダニエル・ハーヴェイは会社のミル・プレーン農場でアメリカの農家が現在(1880年時点)見ているよりも良い小麦の収穫を行っていました」と述べています。

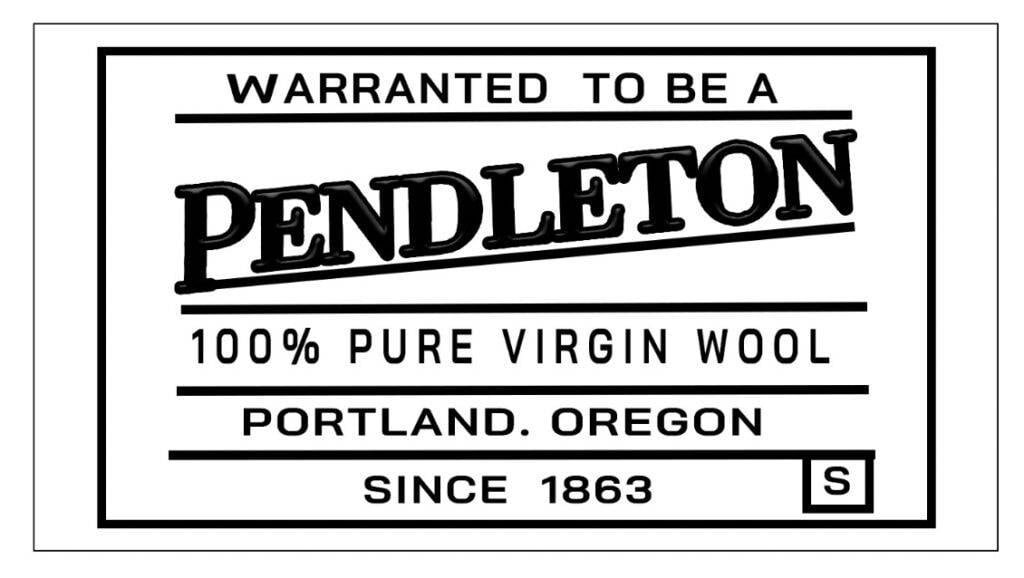

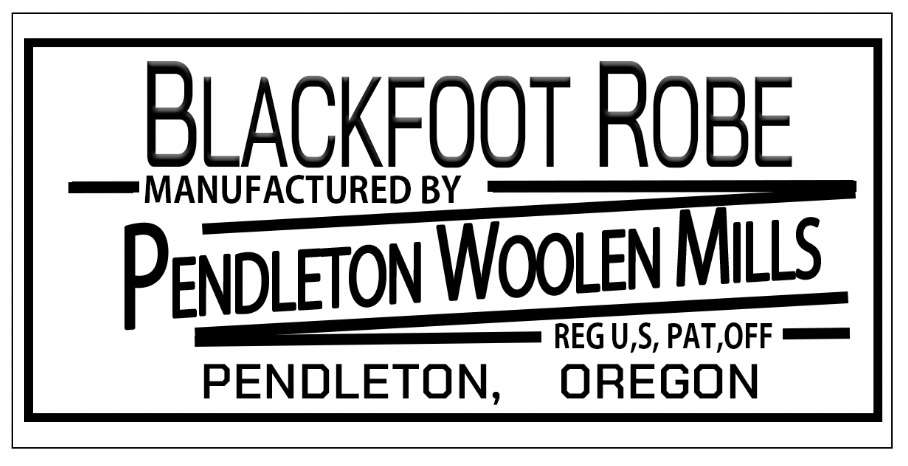

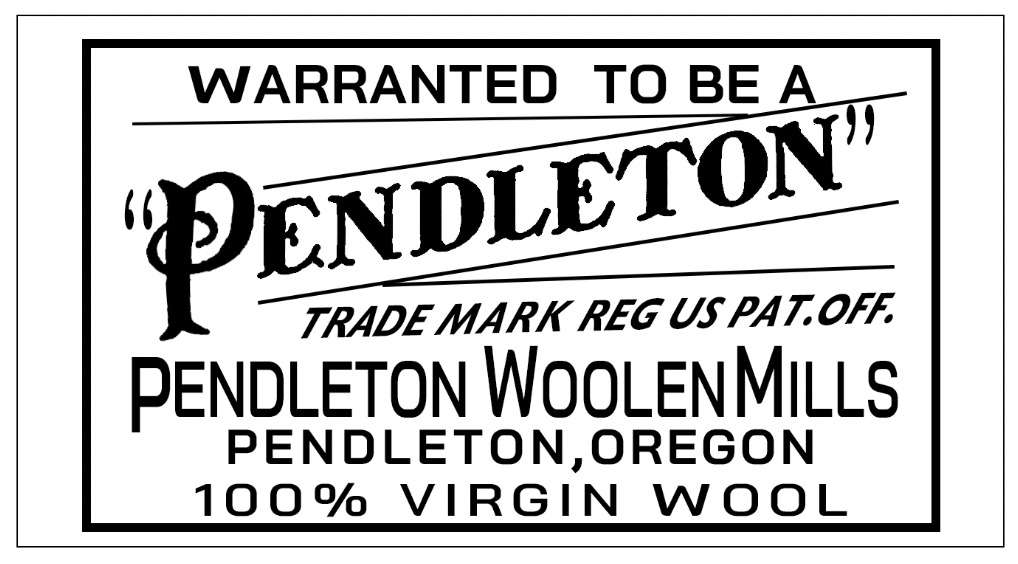

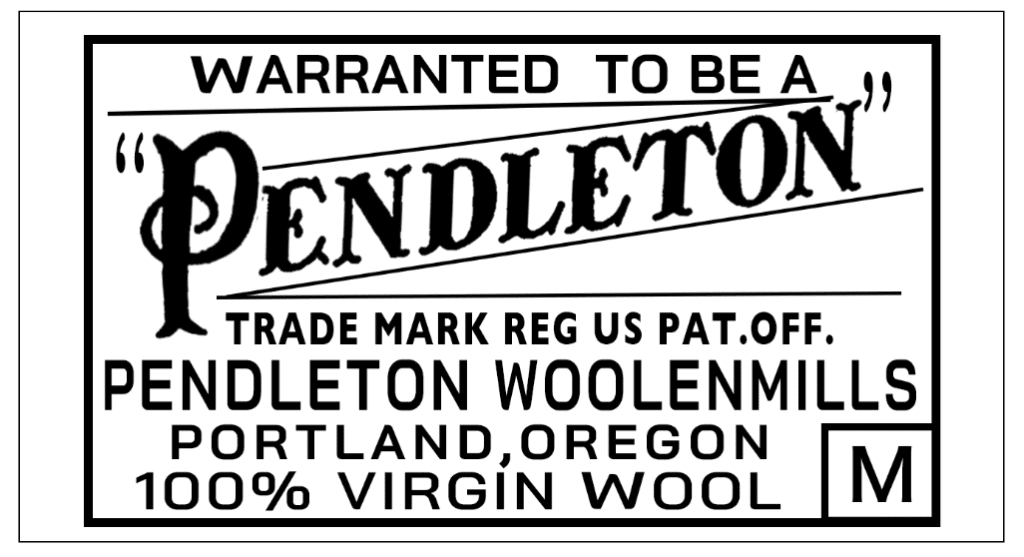

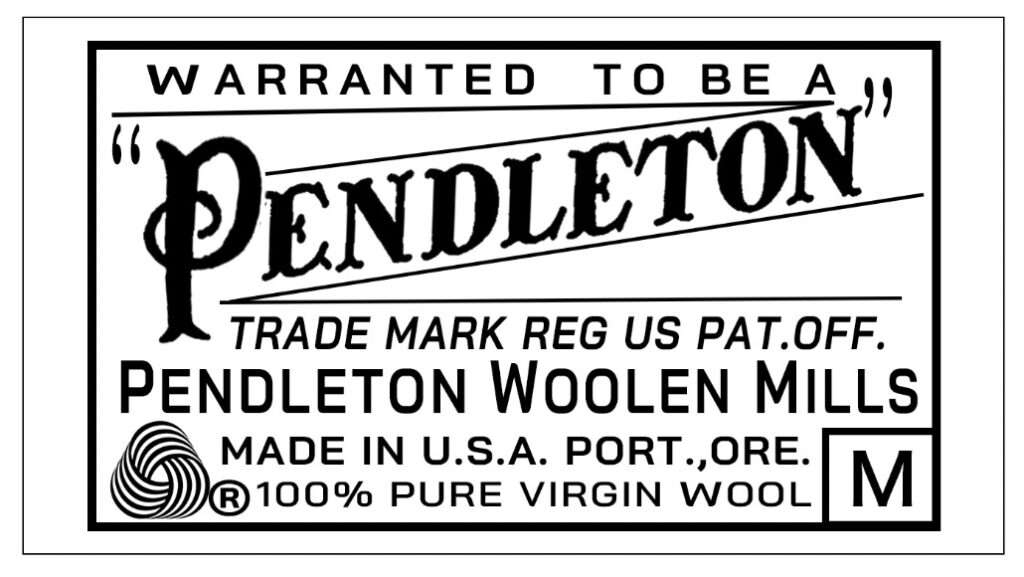

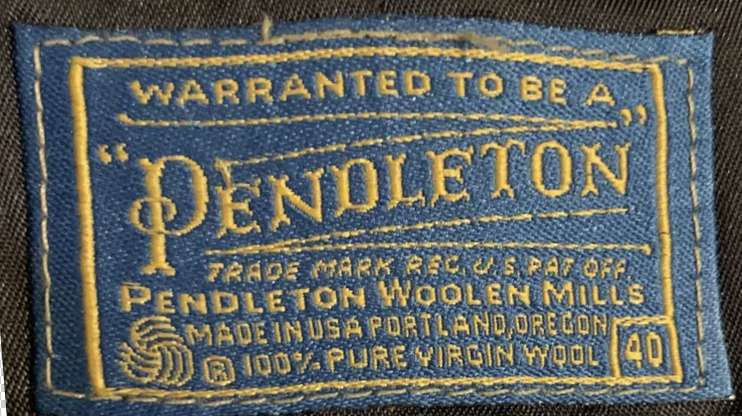

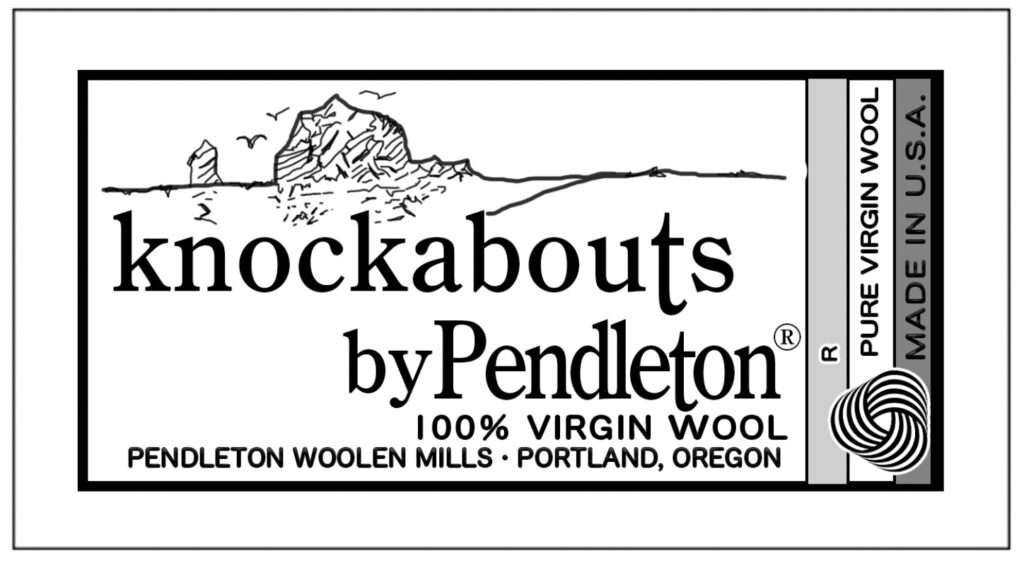

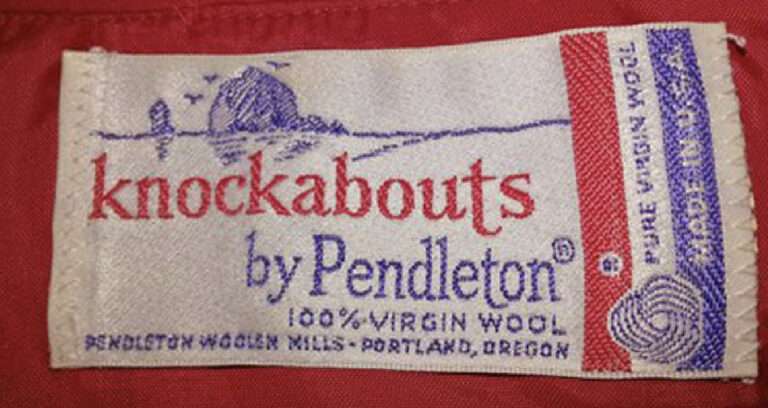

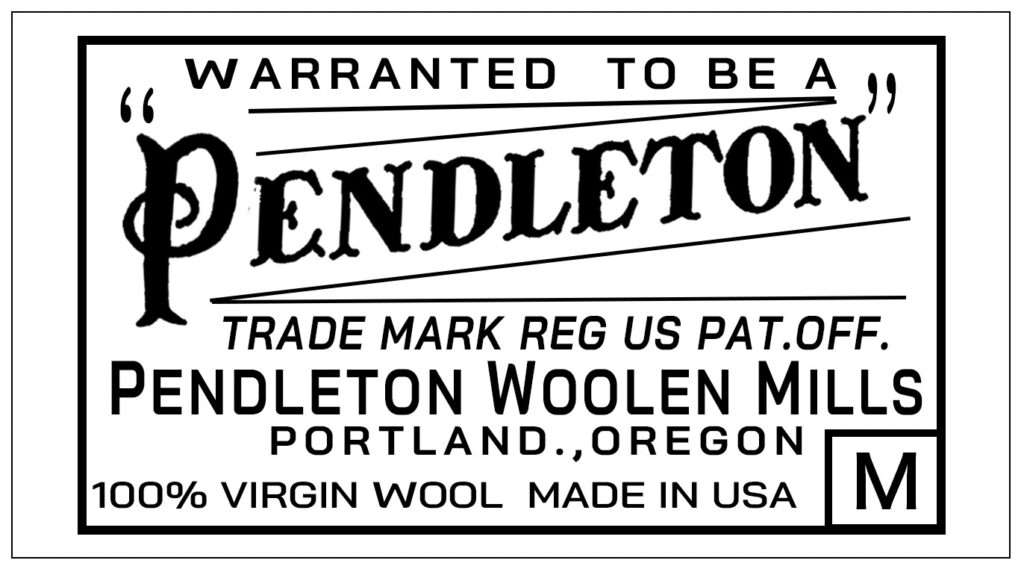

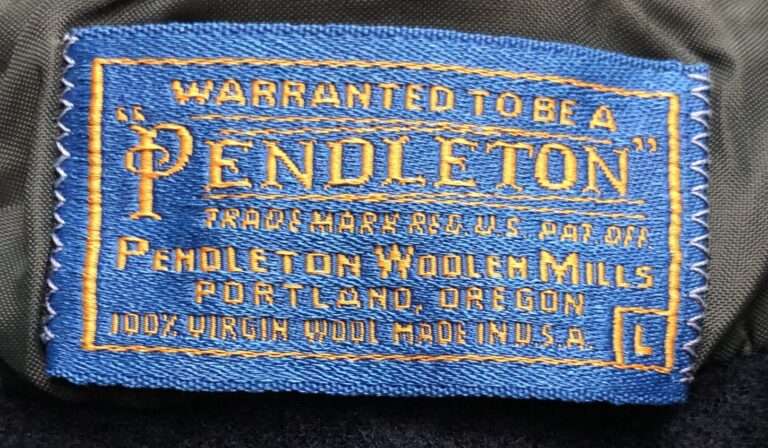

PENDLETON WOOLEN MILLS TAG HISTORY

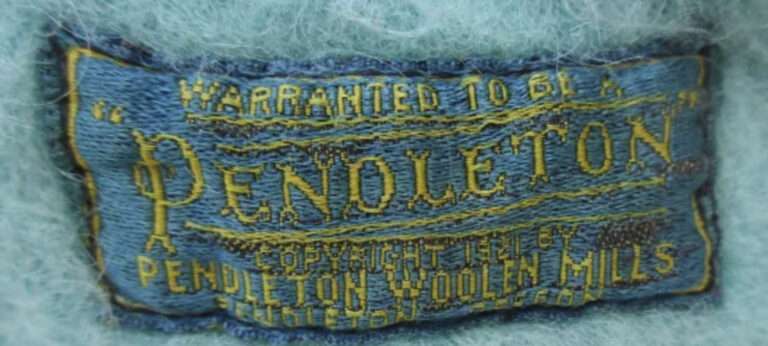

BLANKET TAG

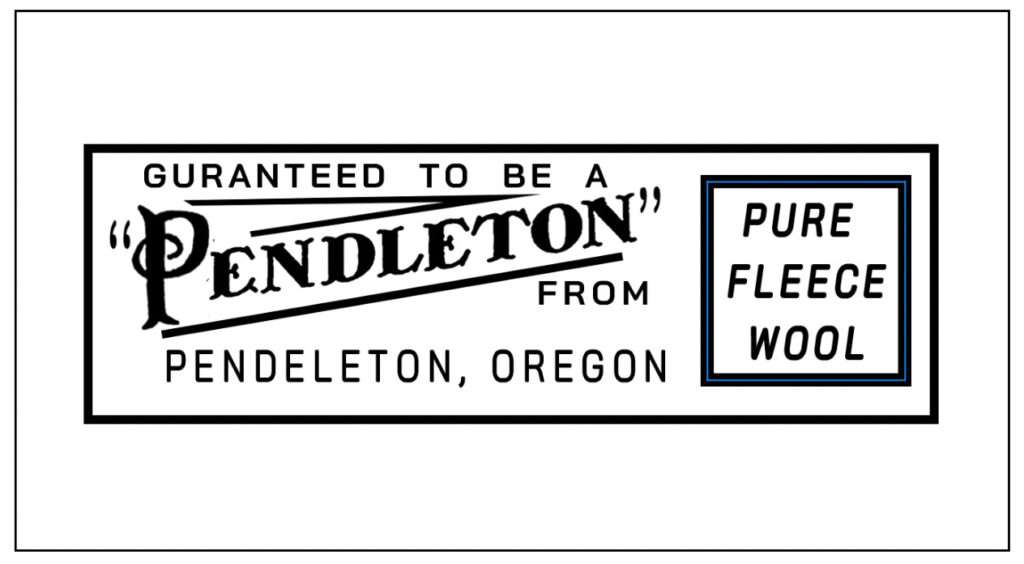

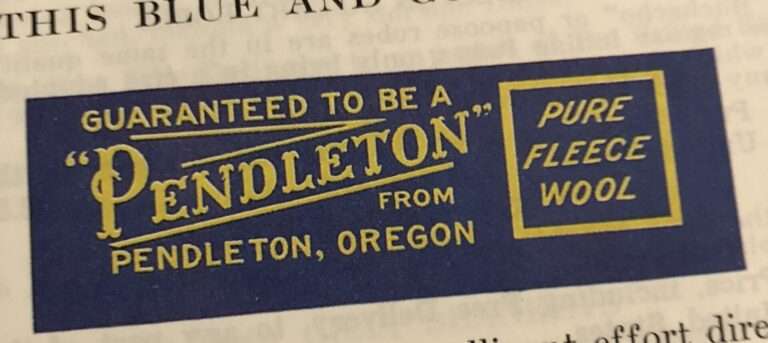

1900s - 1910s

The photographs used as reference were not in very good condition and may be half inaccurate with regard to this figure. It is almost certainly the first Pendleton logo tag made. The book states that it says “guarantee to be a pendleton” instead of “warranted to be a pendleton”, which is usually written from now on, but as the photo is unclear (and damaged), it will take some time to clarify. It also features “PURE FREECE WOOL” as it is a blanket tag. This is the thinnest tag. Furthermore, there is some text under the Pendleton mark, but it is unclear whether it is 100% wool, HANDMADE or, like the other tags, “pendleton woolen mills”, which is currently not known. It is currently unknown whether it is 100% wool, HANDMADE or “pendleton woolen mills” like other tags.

参考にした写真の状態があまり良くなかったために、不明瞭な点がありこの図に関しては半分推測も入っているため不正確かもしれない。しかしこの形で最初に作られたペンドルトンのロゴ・タグであることはほぼ間違いないと思われる。また参考文献によれば、「guarantee to be a pendleton」になっておりこの後歴代続く “warranted to be a pendleton”」かもしれない。写真が不鮮明(かつ傷んでいる)なので、はっきりさせるにはもう少し鮮明な資料が必要であろう。ブランケットなので「PURE FREECE WOOL」と記されています。これは最も縦幅が薄いタグのタグです。さらにペンドルトン・マークの下に文字があるように見えるだが、それがウール100%なのか、HANDMADEなのか、他のタグと同じく「PENDLETON WOOLEN MILLS」なのか、もしくは単なる汚れなのかは今のところ不明です。(fromと判別しました)

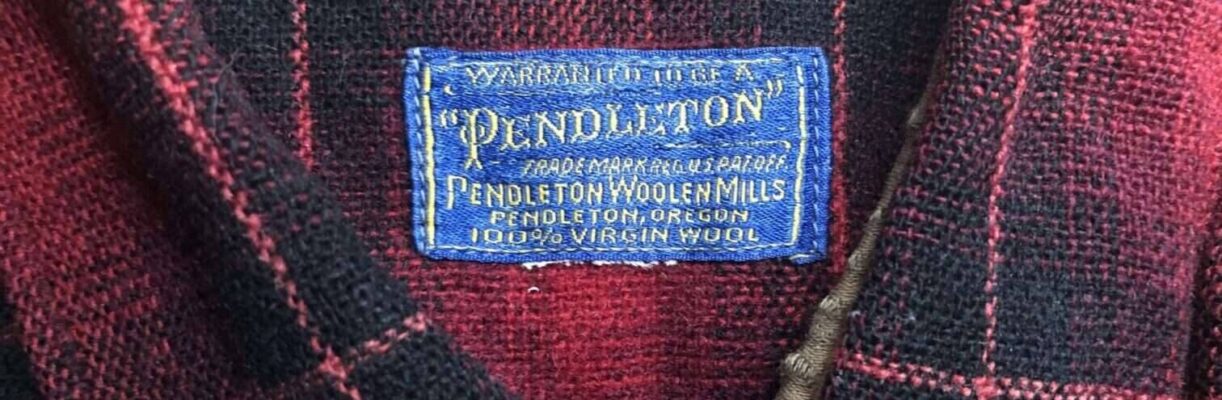

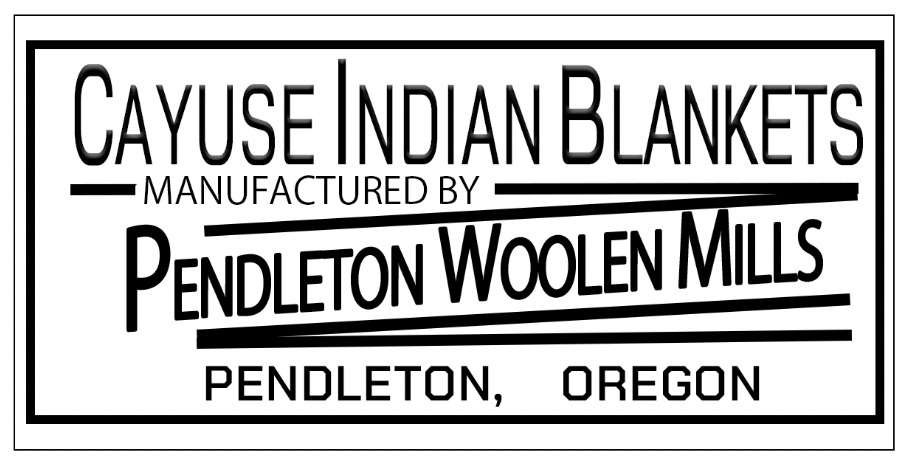

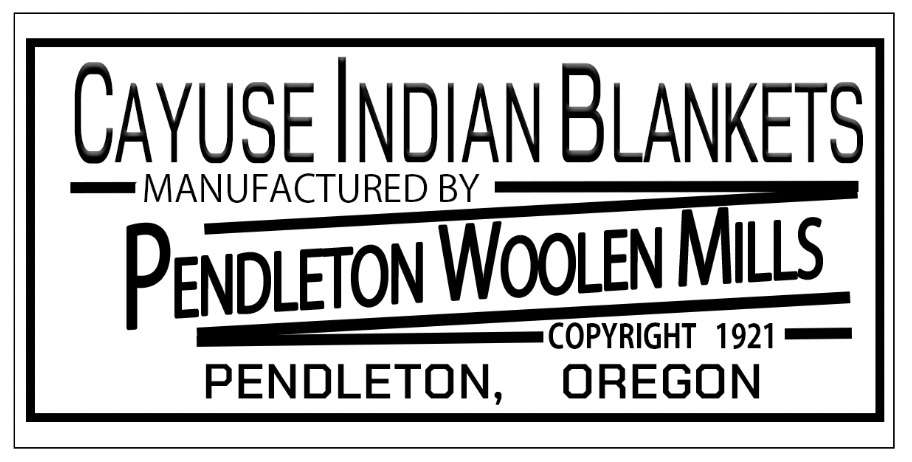

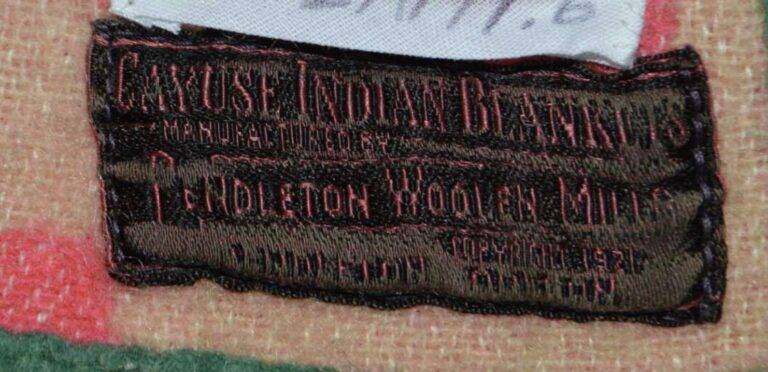

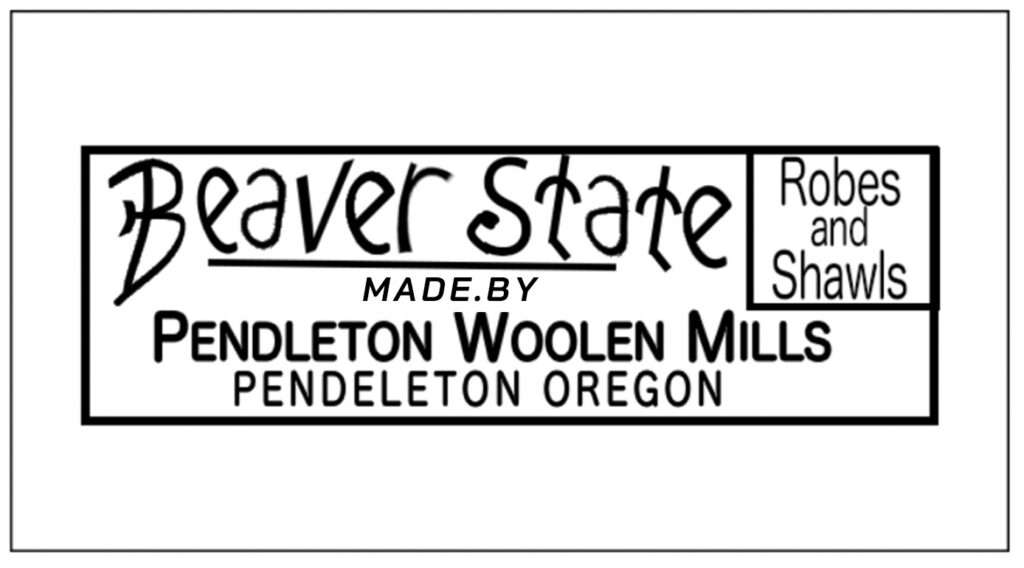

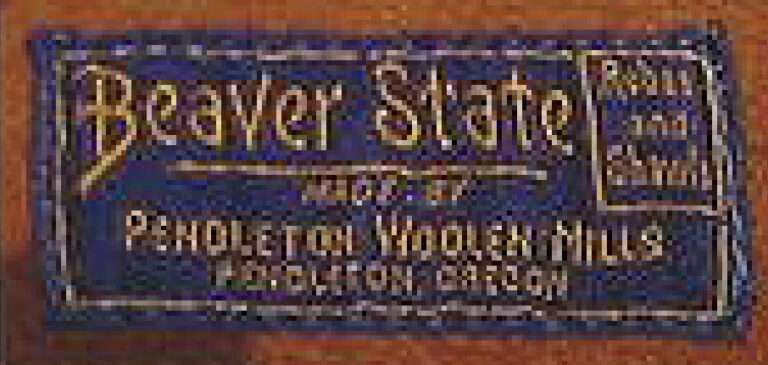

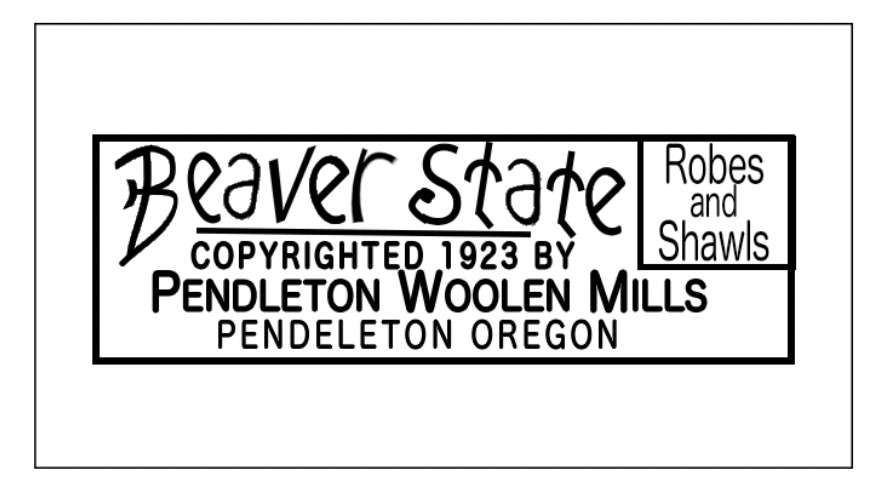

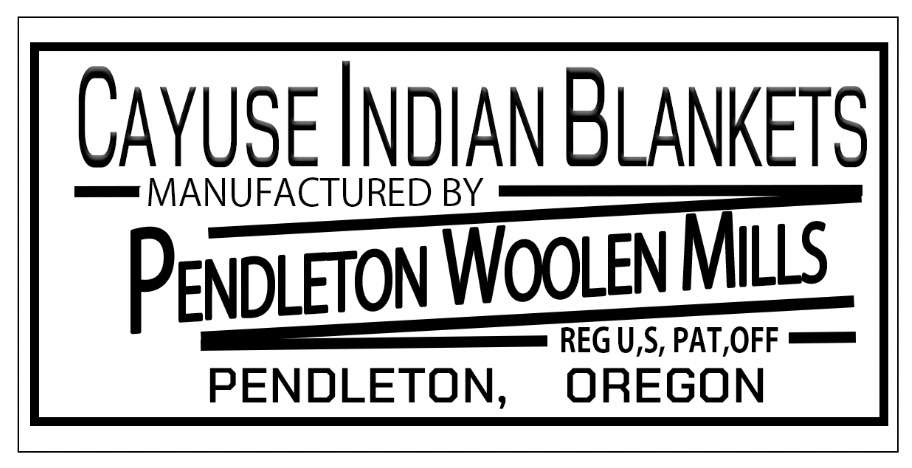

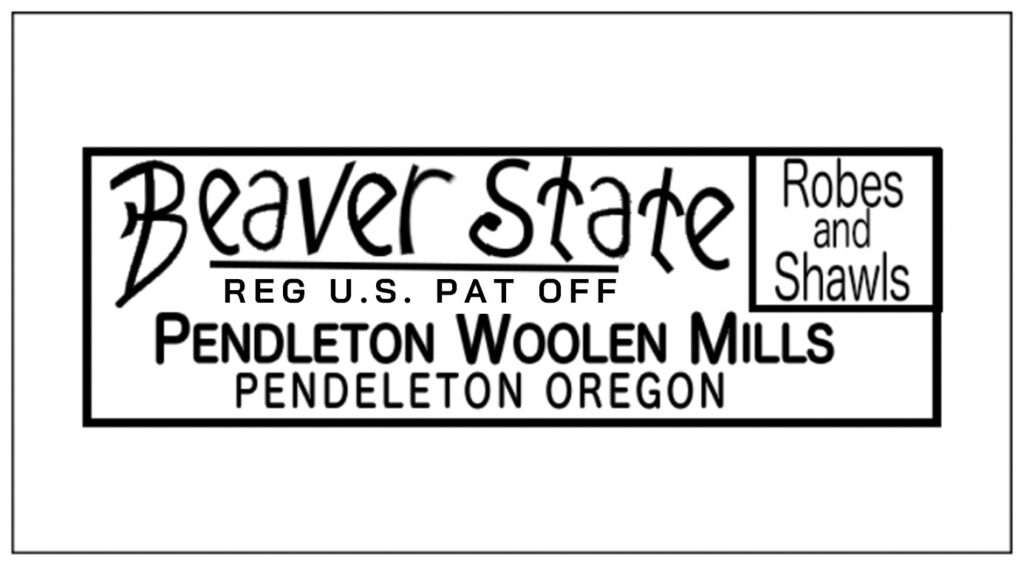

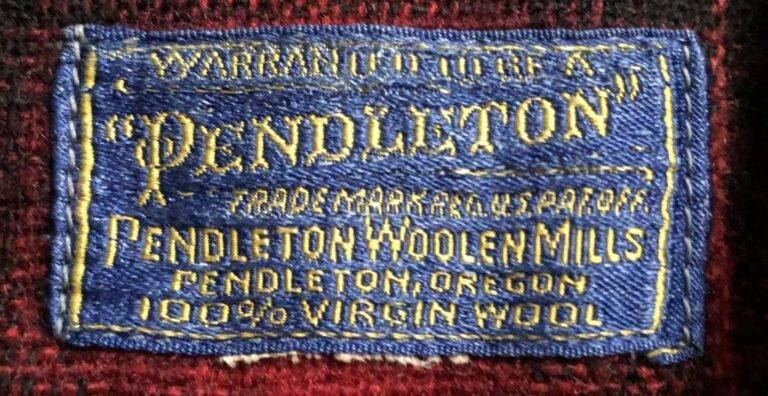

1920s - 1930s

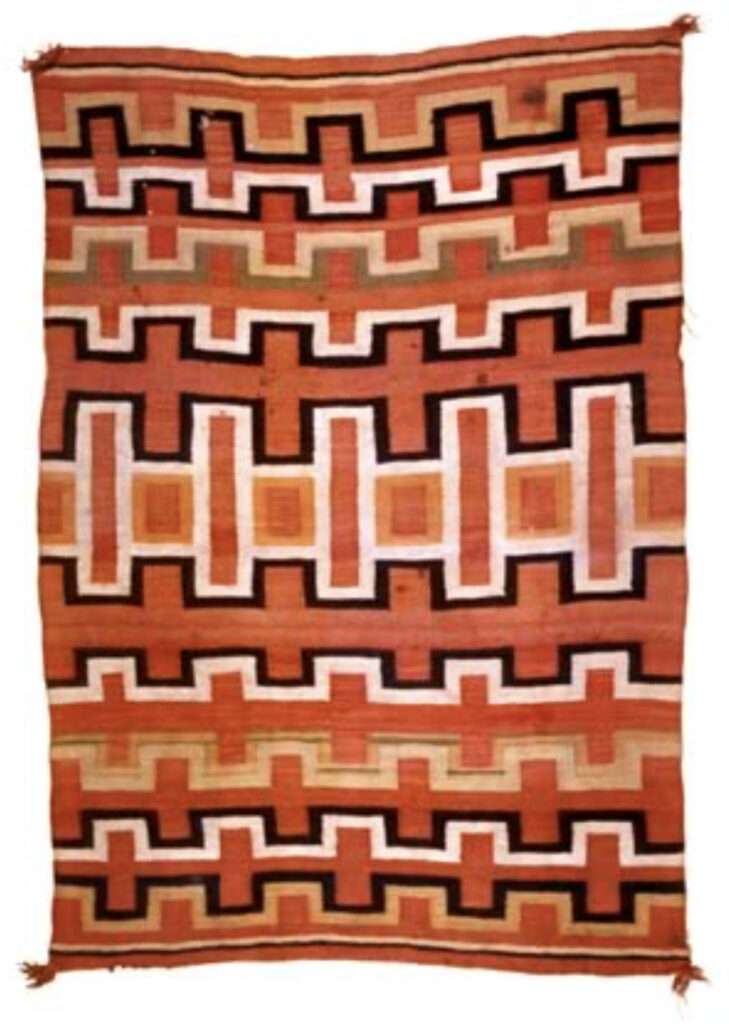

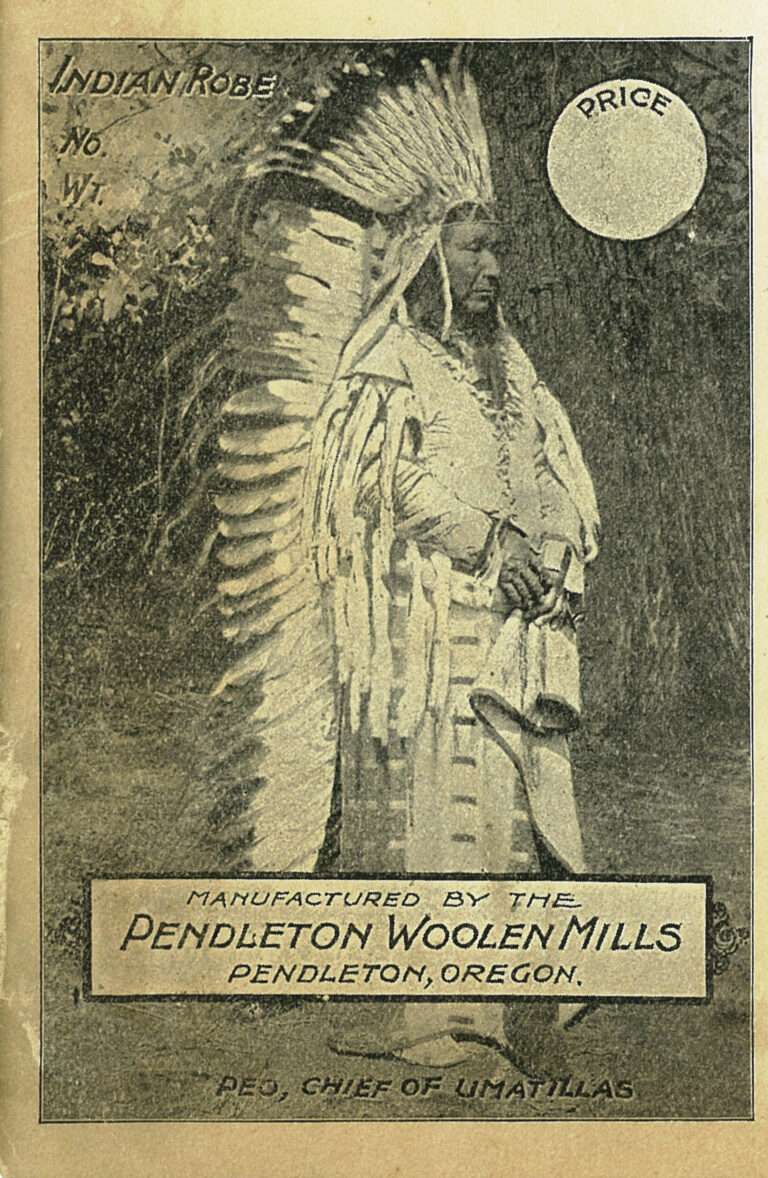

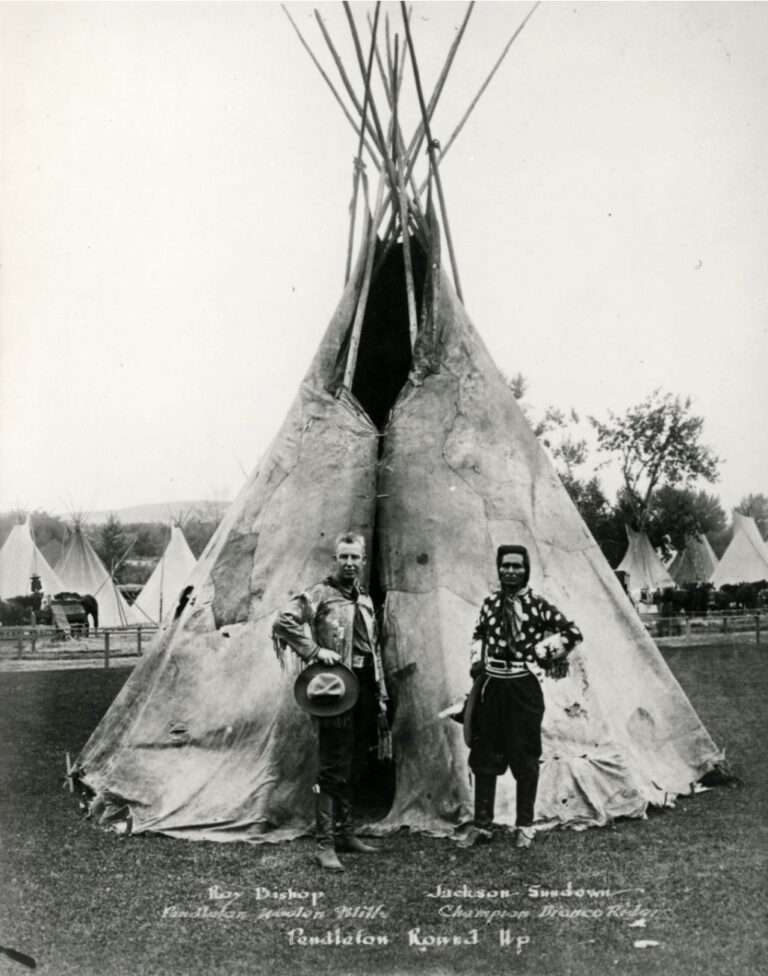

The “Cayuse” are a Native American tribe in what is now the state of Oregon in the United States. The Cayuse tribe shares a reservation and government in northeastern Oregon with the Umatilla and the Walla Walla tribes as part of the Confederated Tribes of the Umatilla Indian Reservation. The reservation is located near Pendleton, Oregon, at the base of the Blue Mountains. As white settlers moved into their territory in large numbers following the opening of the Oregon Trail in 1842, the Cayuse suffered. Even settlers passing through competed with them for game and water. Crowds of whites invaded the region during the California Gold Rush beginning in 1848 and when gold was discovered in Eastern Oregon in 1862.The Cayuse Indians were located in the Columbia Basin and were nomadic, sometimes moving on a daily basis. They lived in teepees, which many nomadic tribes used for portability. The Cayuse were skilled horsemen, and used horses in hunting. They also used them for their trip over the Rocky Mountains each year to hunt a supply of buffalo to bring back for their families. The men hunted game and fished salmon. The women gathered and picked berries and dug and processed roots. The women also processed the animal skins to make materials for shelter and clothing. The men considered bravery to be an important quality, with brave warriors being held in high esteem. The strongest would be made chief.

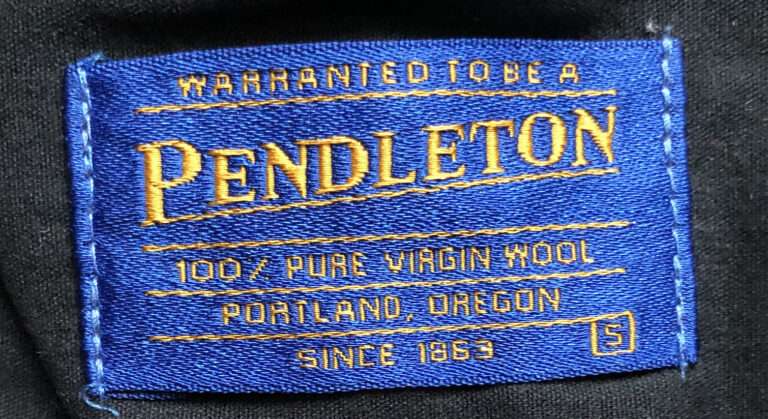

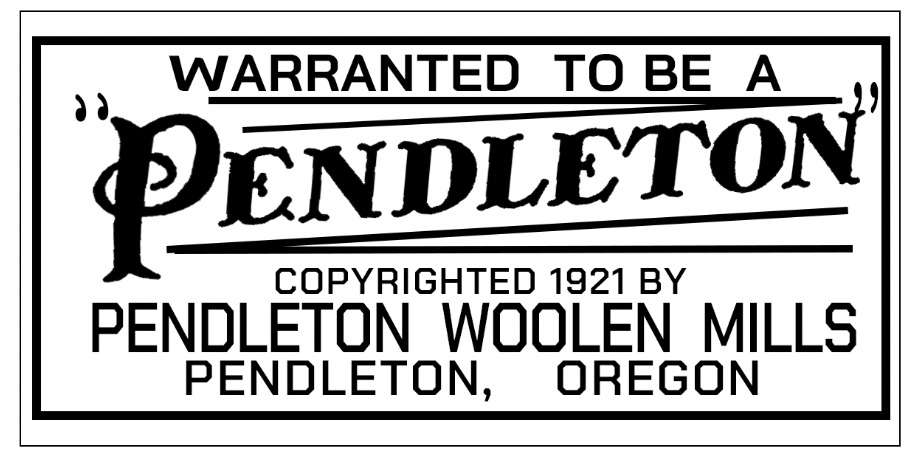

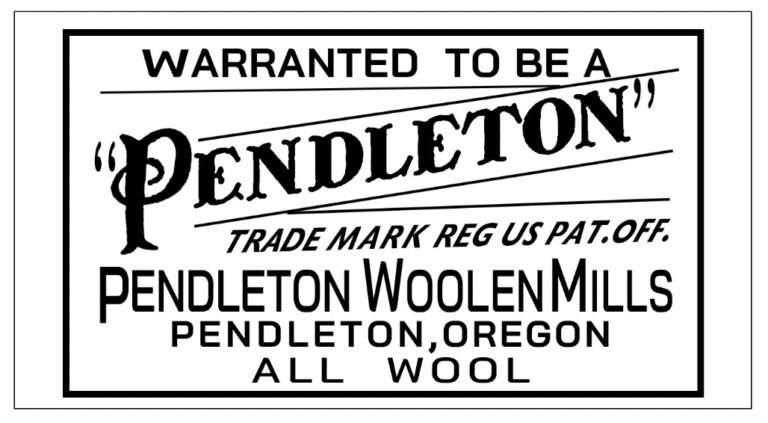

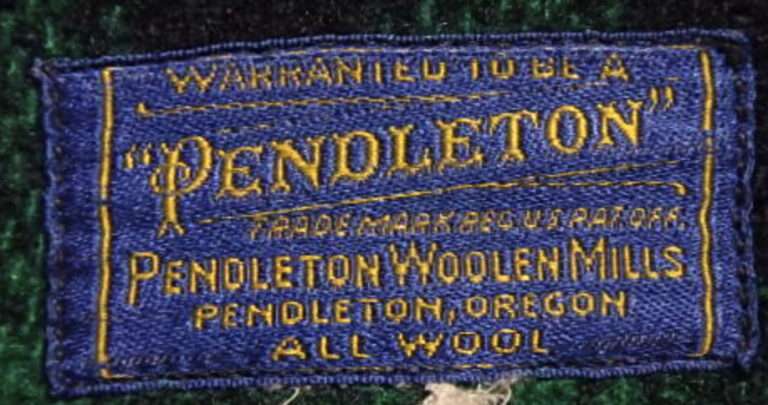

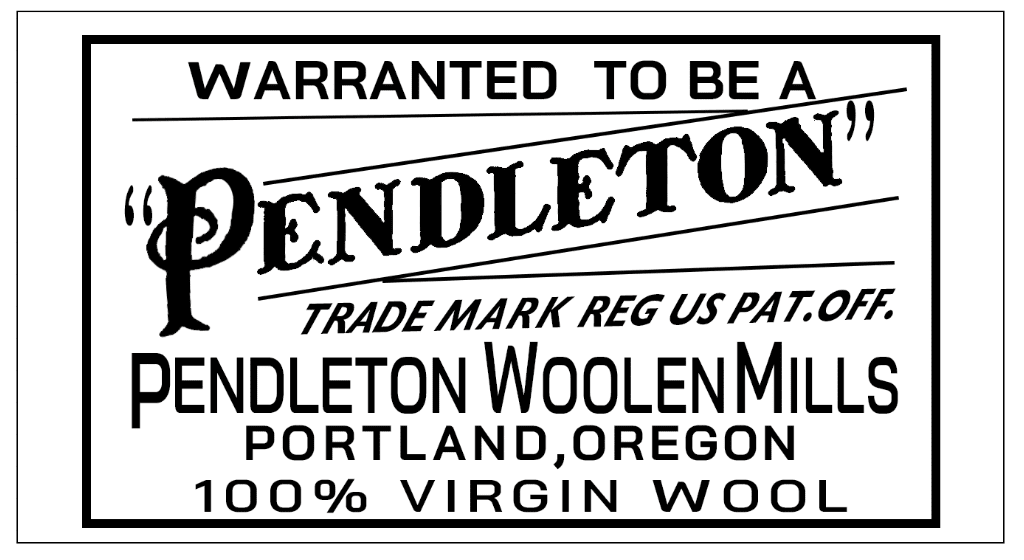

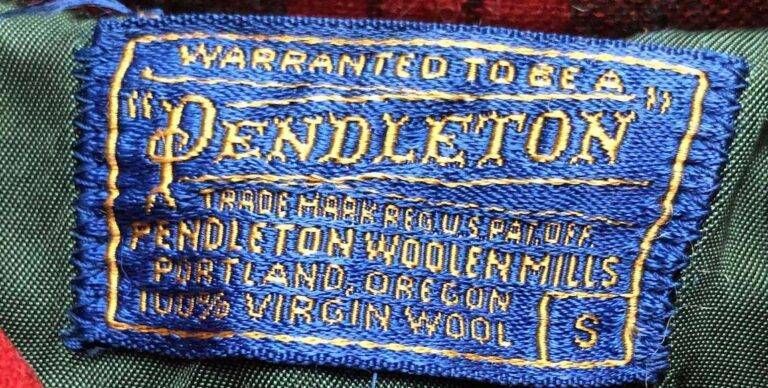

1930s - 1940s

1930 – 1972

Around this year, the name tag was changed because the patent expired. Otherwise, the design is the same. In 1932, Pendleton was awarded the commission to produce a special blanket for Olympic athletes.

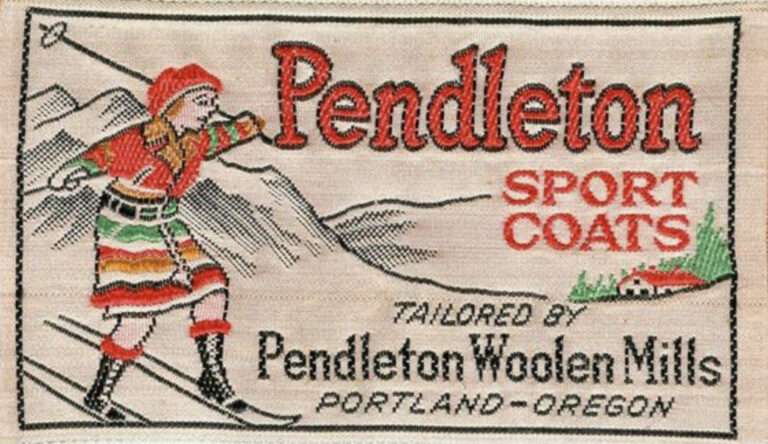

SHIRT TAG from 1924

1924 - 1930s

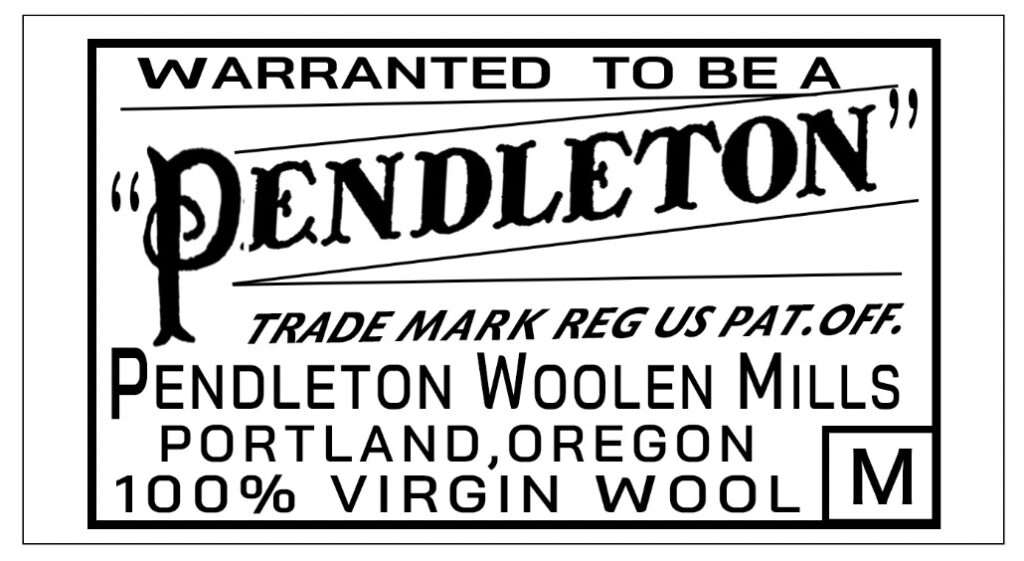

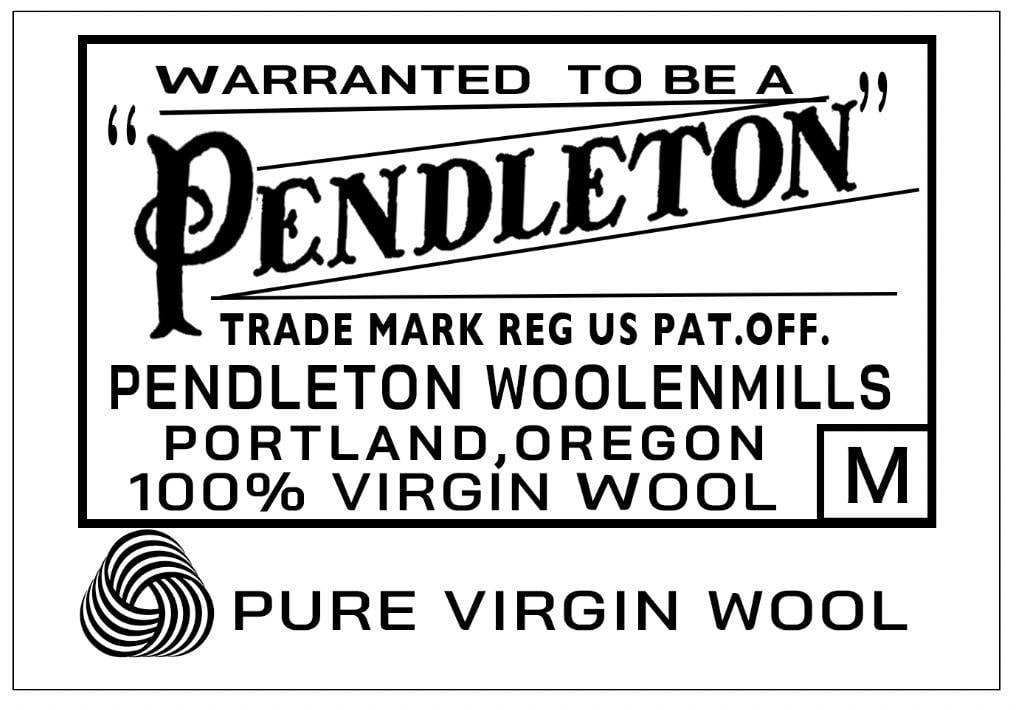

1940s - Early 1950s

Mid - Late 1950s

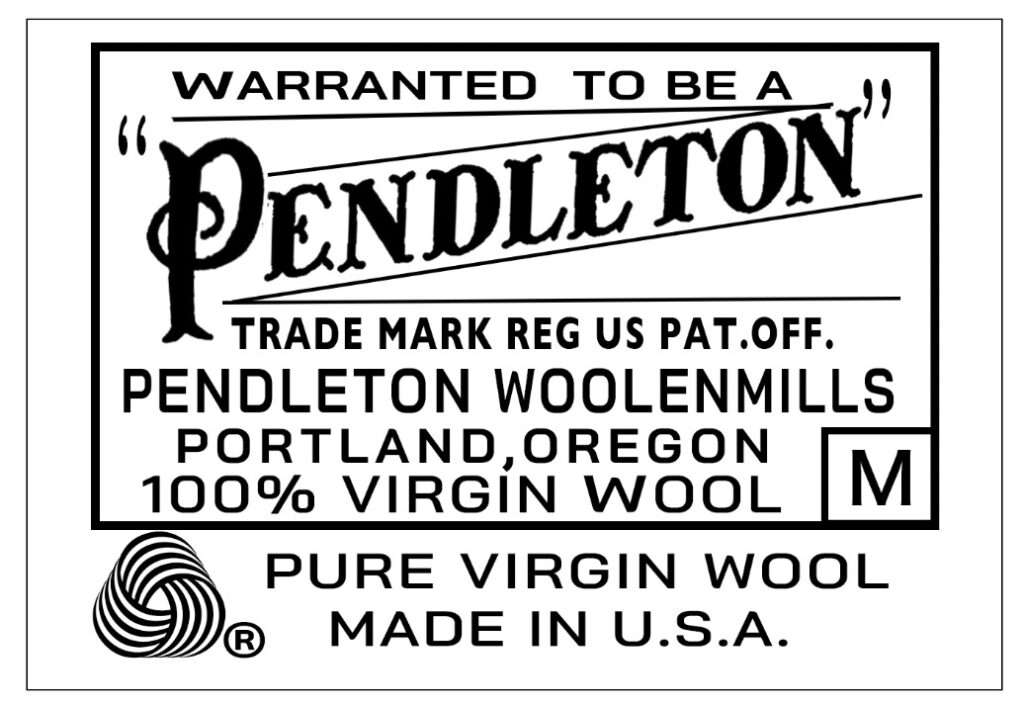

1960s

1964 -

1970s - 1980s

1980s - 1990s

1990s

Late 1990s -